Optimizing the Steam Reformer Process in Indonesia with Carefully Designed Fan Systems

BoldrocchiGroup2021-05-10T14:05:14+00:00Products: Fans

Industry: Fertilizer & Chemical

Location: Banggai Regency, Indonesia

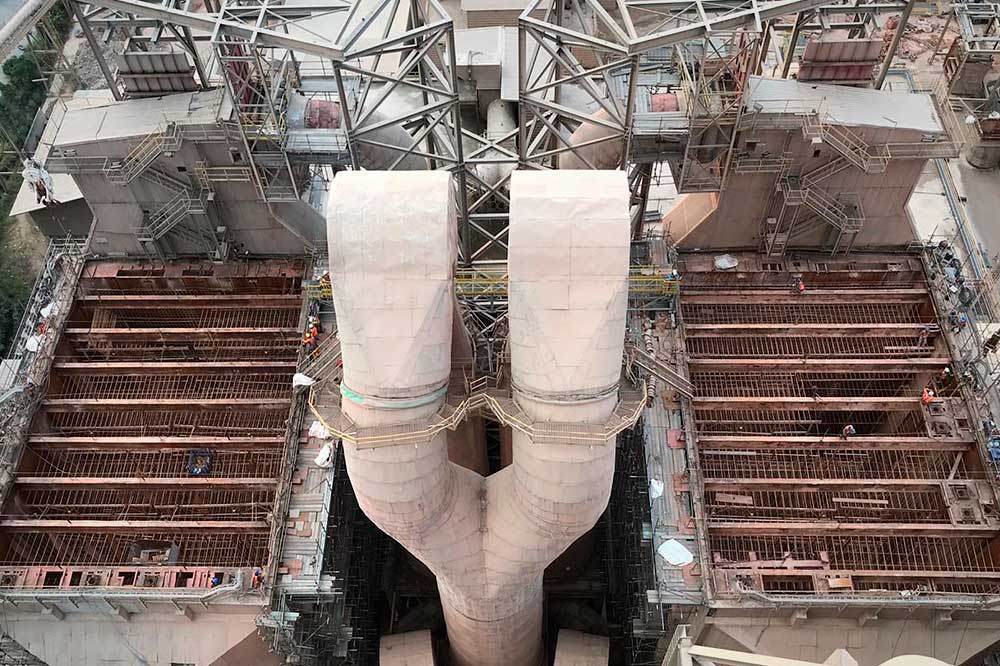

Boldrocchi engineered, manufactured and tested complex fan systems to optimize the steam reforming process at the Banggai Ammonia Project, a new ammonia plant commissioned in 2017 for Panca Amara Utama (PAU), in Banggai Regency, Central Sulawesi, Indonesia. These fan systems are essential to achieving reformer performance targets. They are also highly engineered systems with a complex series of integrated […]