Products: Fans

Industry: Fertilizer & Chemical

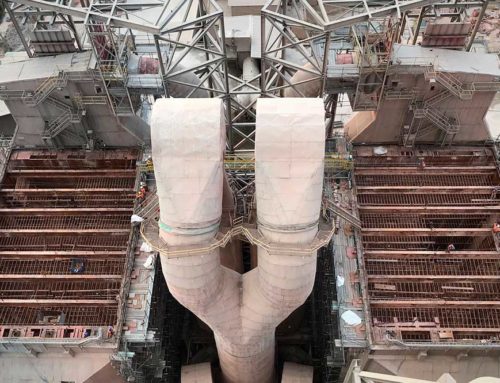

Boldrocchi completed a contract at a nitrogen production plant that was undergoing an expansion. We had been hired to be a single point of responsibility for the complete fan machinery train of the fluid bed urea granulation unit, up to the main process interface. This fluid bed technology is setting the world market standard and Boldrocchi has experience in designing fan systems to optimize production.

Boldrocchi designed, manufactured, did the technical coordination and oversaw the installation of all main components, including the mechanical, instrumentation, acoustic, electrical and piping.

Process Fan Packages

Process fan packages (“fan machinery trains”) are among the most crucial systems in much of the fertilizer process, and urea granulation units are no exception. Indeed fan packages in urea granulation units are directly related to process – and therefore plant – reliability and performance.

Fan packages for this process are also complex to design because a) such large production processes are complicated in themselves; b) the ratings of the units; and c) they require the expertise of a number of different disciplines:

- Mechanical expertise for large rotating pieces of equipment;

- Acoustic expertise to achieve safe noise levels and reach noise reduction goals;

- Filtration expertise to ensure final product is not contaminated;

- Thermal design expertise to ensure heated air is maintained at a targeted constant temperature to preserve the quality of final product;

- Expertise in the piping associated with the layout arrangement and lubrication system;

- Electrical and instrumentation expertise in order to define and program monitoring systems that protect the machinery. This includes anti-surge control systems for the atomization air blower.

Another challenge is designing all these systems for a compact space, in order to minimize the impact on the overall layout of the urea granulation unit.

Fan scope of supply

Over the past 100+ years, Boldrocchi has developed expertise in all the above disciplines. For the project therefore, Boldrocchi supplied complete packages around six fans and one blower, all designed according to demanding API 673 requirements for special purpose units to assure maximum reliability and all designed to fit into the requested space requirements. Fan packages were engineered around:

- First cooler fluidization air fan, rated 450 HP

- Granulator fluidization air fan, rated 2250 HP

- Atomization air blower, rated 2000 HP (main component of double-stage package)

- Granulator scrubber exhaust fan, rated 1500 HP

- Cooler scrubber exhaust fan, rated 450 HP

- Dedusting fan, rated 40 HP

- Fumes extraction fan, rated 40 HP

Erection and Commissioning

Boldrocchi fast-tracked this project and was able to deliver all packages within a short nine months, whereas a typical delivery would take 11 months to a year. Delivery was on time. Erection and commissioning were overseen by a Boldrocchi site expert, who was on-site for two weeks to ensure the proper installation and smooth operation of all fan packages.

Read more about this project in our article “Optimising Fluidised Bed Technology” in World Fertilizer’s April 2018 issue.