Ensuring Quality: Manufacturing, Testing Facilities & Qualifications

Boldrocchi is focused on delivering quality and has its own manufacturing and testing facilities to guarantee production excellence. Additionally, Boldrocchi is well certified and accredited around the world, recognized as providing high quality solutions to its customers.

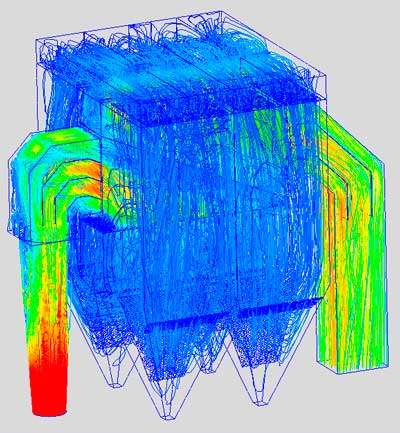

In-House CFD Modeling

Boldrocchi engineers use computational fluid dynamics (CFD) modeling in nearly every project they design. To us, CFD modeling is pivotal to a well-engineered, quality and reliable result. The CFD we use:

- Analyzes the broad physical capabilities of the process

- Ensures optimal internal flow distribution & efficiency

- Minimizes vortex/vibration stress

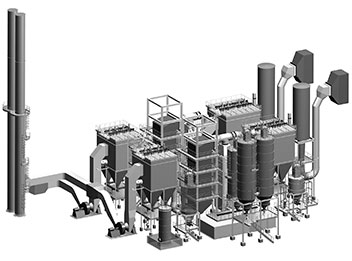

In-House Manufacturing

Boldrocchi has 45,000 m2 (500,000 ft2) of manufacturing facilities. Our worldwide manufacturing is done near Milan, Italy. We have a highly skilled workforce – some of the best tradespeople in Europe – meaning products are sure to be well made, reliable and long lasting.

Facts

- 44 ton balancing machine

- ISO 9001:2008, OHSAS 18001:2007, UNI EN ISO 3834-2:2006, EN 1090-1:2009 + A1:2011

- Over 200 welding procedures qualified

- ASME, AWS or EN norms

In-House Testing

Boldrocchi is one of the few manufacturing & engineering companies in the world to have their own testing facilities. We have three in-house testing centers offering:

- Nondestructive testing (NDT)

- Rotor balancing

- Hot gas testing

- Acoustic compliance

- Mechanical strength (up to 500 bar)

- Fan performance (up to 2000 KW)

- ASME & PED hydrostatic

- Running test for fans & heat exchangers

- World’s biggest fan test rig

- Complete pre-assembling

Qualifications

Constructive Qualifications

ARAMCO

ASME-U

EIL (India)

ENEL

Lloyd’s

Users / Licensors

ENI

Shell

Total

ExxonMobil

Chevron

Dow Chemical

Aramco

SABIC

ADNOC

ADGAS

ADCO

GASCO

Takreer

NIOEC

Petrobras

PDVSA

EIL

PDIL

Enel

SEC

KBR

Haldor Topsoe