Products: Heavy-Duty Process Dampers

Industry: Oil & Gas

Location: Lekki, Nigeria

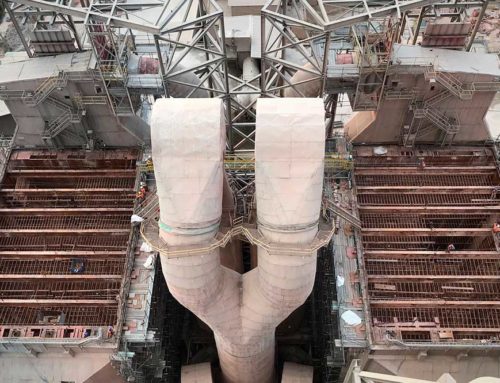

In 2016, Boldrocchi was awarded a contract to supply eight (8) diverter damper systems for six GE gas turbines, to be installed at the Dangote Refinery in Lekki, Nigeria. The goals: achieve reduced wear & extended operational life. Thanks to our large in-house facilities, all 8 were assembled at once. They were then tested in-house in the presence of the customer’s inspectors. Turnaround was very short – at least for the first two – and Boldrocchi delivered within a mere four months.

Scope of supply

- 8 electrically-operated diverter damper systems each fitted with a guillotine and sealing-air fan skid

Superior engineering

Our zero-leakage sealing technology and the actuator systems were tested in Boldrocchi’s testing workshops near Milan, Italy and withstood 3 times more back-pressure than specified by the customer. Consequently, the wear on elastic parts will be reduced and operational life extended.

In-house testing

All units were fully assembled and tested in the presence of the customer’s inspectors at Boldrocchi’s new testing facility, in compliance with strict product control procedures and standards.

Expert in-house manufacturing & pre-assembly

Thanks to our large in-house facilities, we managed to assemble nearly all eight at once. Needing to be transported by truck to GE in Tuscany, each diverter was pre-assembled into two parts. GE was then easily able to re-assemble them into a single machine on the deck before shipment to Nigeria.

Rapid turnaround

Boldrocchi was able to design, manufacture, assemble, test and ship the two first diverters in a mere four months. The others were sent on time, as per the schedule.

To learn more about this project, please read our article “Boldrocchi Project for Dangote Refinery in Nigeria” in Industrial Plants, May 2017.